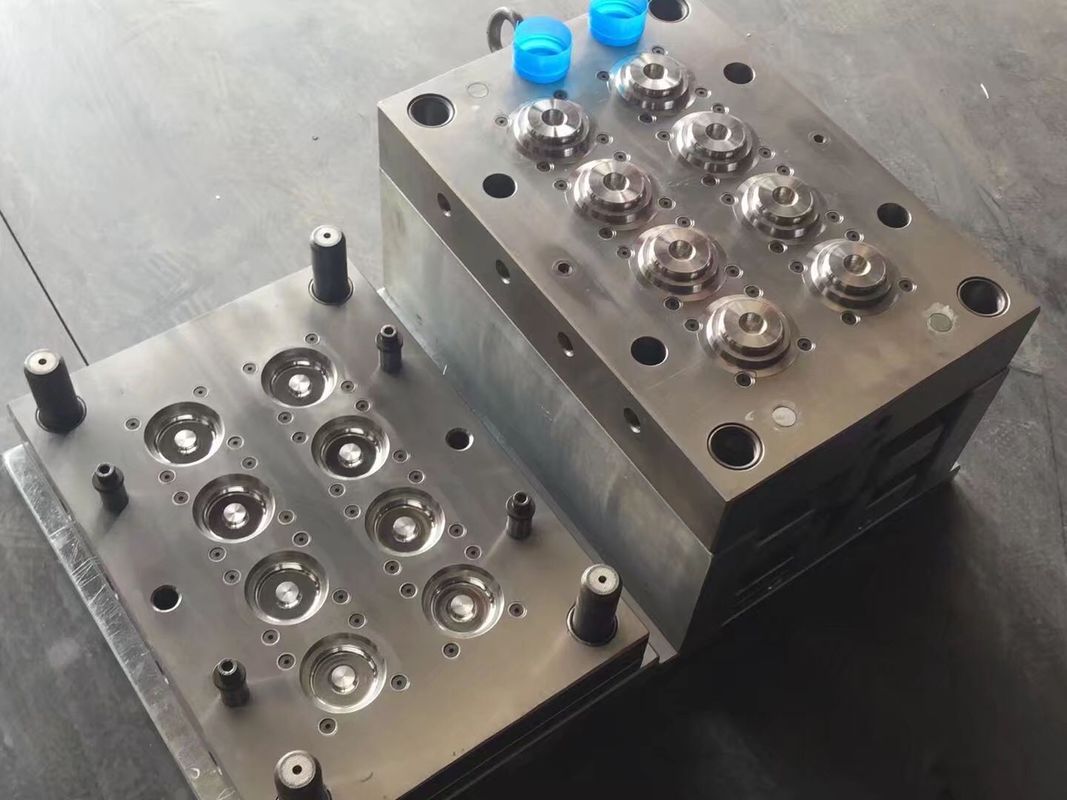

PET Water Drink Bottle Cap Auto Injection Molding Machine 8 Cavities 250 Ton

Product Details:

| Place of Origin: | China |

| Brand Name: | Taihong |

| Certification: | ISO9001 |

| Model Number: | bottle cap moulds |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | negotiable |

| Packaging Details: | Export standard |

| Delivery Time: | 45days |

| Payment Terms: | T/T |

| Supply Ability: | 20sets/month |

|

Detail Information |

|||

| Mould Material: | NAK20,S136,P20.718H,738H,45#,etc | Mould Base: | LKM;HASCO;DME,etc |

|---|---|---|---|

| Runner: | Hot/cold Runner | Cavity: | 8 Cavities |

| High Light: | pvc pipe fitting injection molding machine,servo motor injection molding machine,hydraulic plastic injection moulding machine |

||

Product Description

PET water drink bottle cap Auto Injection Molding Machine 8 cavities

Mould Information:

| Mold information | content |

| Product Material | ABS,PP,PC,PA,PMMA,PS,POM and etc. |

| Moldbase | FUTABA,LKM,HASCO,DME you can choose |

| Cavity material | 45#,50#,P20,H13, 718 2738, NAK80, S136, SKD61 etc |

| Runner | Cold/Hot runner |

| Cavity | Multi or single cavity |

| Standart parts | Hasco |

| Gate type | Side gate,Sub gate,Pin point gate,Edge gate etc |

| Treatment | Heat treatment and Nitriding,polish ect. |

| HRC | H45~52 |

| Product weight | 50~5000K |

| Machine type | 250Ton |

| The standard of appearance of the products for stripe | MT(Mold Tech),YS,HN series |

| The way of Color contrast | RAL K7,PANTONE |

| Plastic Mold (Moulds) production process | Description |

| 1. 3d Design/Samples for quotation | According to 3D drawing or samples for quotation. |

| 2 .Negotiations | Including the price of moulds, moulds sizes, material for cores & cavities, weight of product, part cost, payment, moulds lifetime, delivery, etc. |

| 3. Purchasing Order | After the customer confirming the mould design and quotation. |

| 4. Making mold(moulds) | Confirm drawing, start to do DFM,mold flows and mold detail agreed with the customer, start production. |

| 5. Production schedule | Every week we will feedback to the customer a mold progress(picture). |

| 6. sample shoot | We provide the moulds test samples for confirmation(about 10-15 piece), then, get your signature sample ,mass production. |

| 7. Package | Wooden case for moulds, cartons for parts ,or as your requiretment. |

| 8. Delivery | deliver goods by air or by sea. |

Advantages of injection plastic parts

- Competitive price

- Continuance service and support

- Diversified rich experienced skilled workers

- Custom R&D program coordination

- Application expertise

- Quality,reliability and long product life

- Mature,perfect and excellence,but simple design

Steps of injection plastic parts

- Negotiations: Quality,material,price,payment,delivery time item and so on

- Place an order: According customer's drawing or sample

- R&D: According customer's requirements,we could design or improve 3D modeling

- Design confirmation: We send 3D drawing to customer for confirmation before we make the mould

- Mould processing: CNC EDM machine processing then assembly and trial

- Sample confirm: We will send trial sample to customers.Before shipment,If the sample isn’t satisfied by customers.We will modify mould until they are satisfied.

- Mass production: If customers need mass production of plastic products,We can offer

- Manufacturing Package and Delivery

Want to Know more details about this product