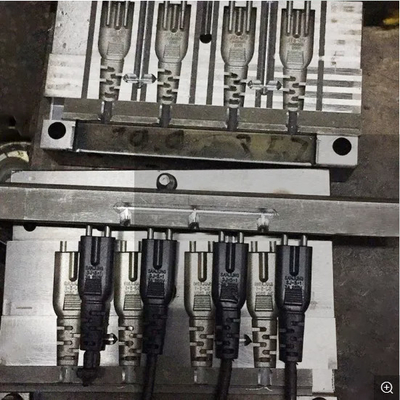

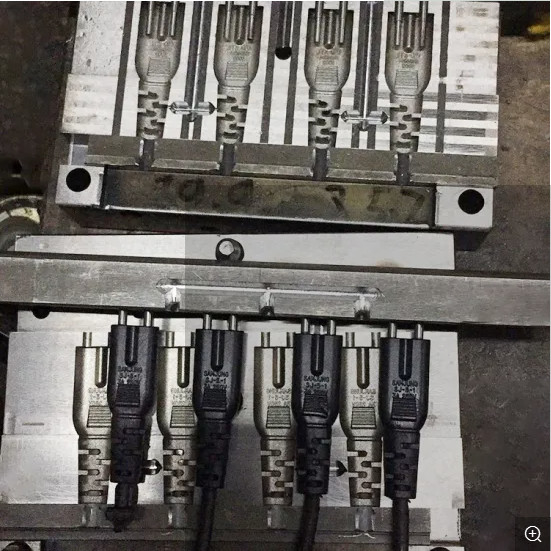

Product Description

Precision Plug Making Mould

Specifications:

Design: We use the most advanced mould design software Auto CAD, UG

Manufacture: We use With advanced technology, unmatched skill, professional and advanced equipment size range from 45T-400T, and experienced technicians to fit our customers requirements, like tooling manufacturing, stamping and surface treatment service

Product Material: Stainless steel

Making process and Capability: Progression die, Stamping, deep drawing, Bending, Punching, Threading, Tapping, Riveting, Grinding, CNC machining, Metal Fabrication,forming,Stretch forming,,Assembling, Blanking and so on.

Price Terms: FOB SHANGHAI, CHINA

Lead time: 20-50days based on the different products

Packaging: canton case or as per customers' requirement

Certification:ISO9001,IATF16949,SGS

Industry: these parts are used in Automotive, Electrical, Building, Furniture, Machine assembly, Computer, Air industry , Oil field Equipments, Marine equipments, Mine equipment,Agricultural Machines,Transportation Equipments, OEM/ODM Electronics......

High precision Customized Plastic injection mold

| Product name | High precision Customized Plastic injection mold |

| Mold shaping | Plastic Injection molding |

| Mold base | LKM;HASCO;DME,etc |

| Mold material | NAK20,S136,P20.718H,738H,45#,etc |

| Mold cavity | Single or Multi |

| Tolerance | +/-0.02mm |

| Finish | Anodized,Polish,Silk-screen,Painting,etc |

| Sprue gate | Hot/cold runner;pin-point gate,etc |

| Design software | UG,PROE,CAD,SOLIDWORK,etc |

| Product material | ABS,PP,PE,POM,PMMA,etc |

| Mold life | 100k-500k shots |

| Lead time | 25-45 days |

| Transportation | By sea, by air or by land as you request |

| Package | Standard or as you request |

| OEM/ODM | Acceptable |

| Certificate | ISO9001:1008,SGS, |

Specifications of injection plastic parts

| Item | Description |

| Product Name | Plastic part |

| Working Process | Plastic injection |

| Material | ABS, PC, PP, PS, POM, PMMA |

| Mould Base Material | LKM, FUTA, HASCO, DME, etc. or as per customer' s requirement. |

| Surface treatment | Polishing plating |

| Color | Red, blue, green, yellow |

| Packing | Inner-Plastic Bag; Outer -Standard Carton Box. |

| Usage | All kinds of cars, machinery, home appliance, electronic products, electric appliance, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more |

| Quality Control | Conducted by ISO9001 |

| Cavity Number | Single cavity, Multi Cavity, based on customer' s requirement. |

| Applications | auto,motorcycle,industry,ariculture,mine,furniture,elevator,etc |

| Equipments | CNC,EDM,ArgieCharmilles,Milling Machine,3D CMM, Projector,HG,Injection Machine |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

| Service | Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

| Inspection | IQC, IPQC,FQC,QA |

Plastic Mold (Mould) production process:

1. 3D drawing/Samples for quotation: According to 3D drawing or samples for quotation.

2. Negotiations: Including the price of moulds, moulds sizes, material for cores & cavities, weight of product, product color, payment, moulds lifetime, delivery, etc.

3. Purchasing Order : After the customer confirming the mould design and quotation.

4. Making mold(moulds): Confirm drawing, start to do DFM, mold flows and mold detail agreed with the customer, start producion.

5. Production schedule: Every week we will feedback to the customer about the mold progress(picture).

6. Sample shoot: We provide the moulds test samples for confirmation(about 10-15 piece), we will start mass production when get your signature samples.

Plastic molding Specification

1. Professional manufacturer,design,production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint