HAIJIANG INJECTION MOLDING MACHINE FEACHURES

-Bigger space between tie -bars

-Central -clamping structure

-Famous components

-Energying saving with servo moter

-Low noise ,fast response

-High precision ,stable and super long life

-T-slot platen

-Abudand spare parts

-Better price .

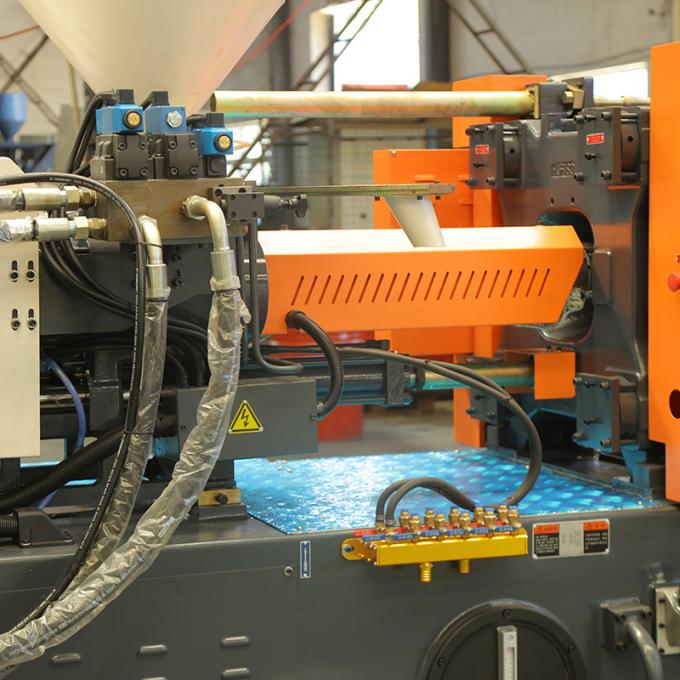

The Clamping Parts

The new generation mold locking device and computer emulation optimized parameter makes motions of the moving plate, fixed plate and high rigidity toggle structure, the characteristic of high strength and anti-fatigue is secured. As compared with similar machines, it owns bigger internal spur between tie bars, mold space and mold opening stroke and may process plastic products of bigger size.

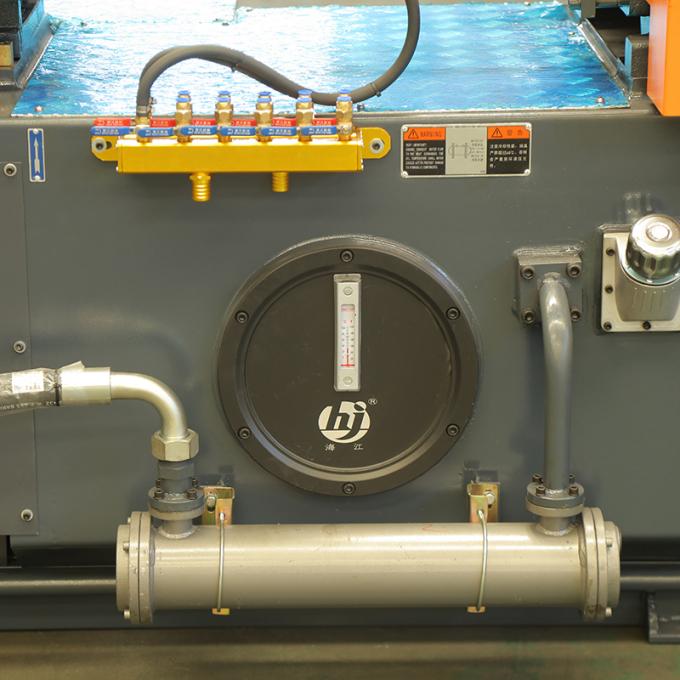

The Hydraulic Units

High efficiency, Energy-saving and high precise proportional pressure and flow variable displacement pump system make the out of the hydraulic system matching the required power for entire machine operation without loss of high pressure throttle and overflow energy. As comparedwith constant displacement pump, t saves power by 30%~60%.A motor with same power may be fitted with an oil pump of bigger displacement and thus accelerates the speed of machine.Besides, the low oil temperature will prolong the service life of sealing elements.

Injection Units

High injection pressure ,fast injection speed

The screw check head and check ring are made of hot tool steel imported from Japan and flame hardened by vacuum ,with high temperature resistance ,wear resistance and corrosion resistance.

FAQ

1.Q: Are you a manufacturer or trading company?

A: We are a professional injection molding machine manufacturer.

2. Q: Where is your factory located?

A: Our factory is located in Ningbo city, China.

3. Q: How could we confirm the details of the products?

A: We will provide all the drawings for you to confirm before production. And we'll also provide online remote meetings with our professional engineers to you.

4: Q: How long the warranty will be?

A: 18 months warranty for the whole tank and the main equipment, we will also send you some free accessories and auxiliaries.

5. Q: How about the installation?

A: We can supply the installation. There are two options.

Option 1: We could appoint our engineer to your company to debug and repair, as for the

cost of this trip such as ticket, visa, accommodation and labor cost shall be on your side.

Option 2: On-line service will be provided. If still under guarantee period, the necessary accessories and parts will be provided free, but the transportation cost of it shall be on you side.

6. Q: How do you guarantee machine operation?

A:Before out of factory, we will test the injection molding equipment and send you operating videos.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!