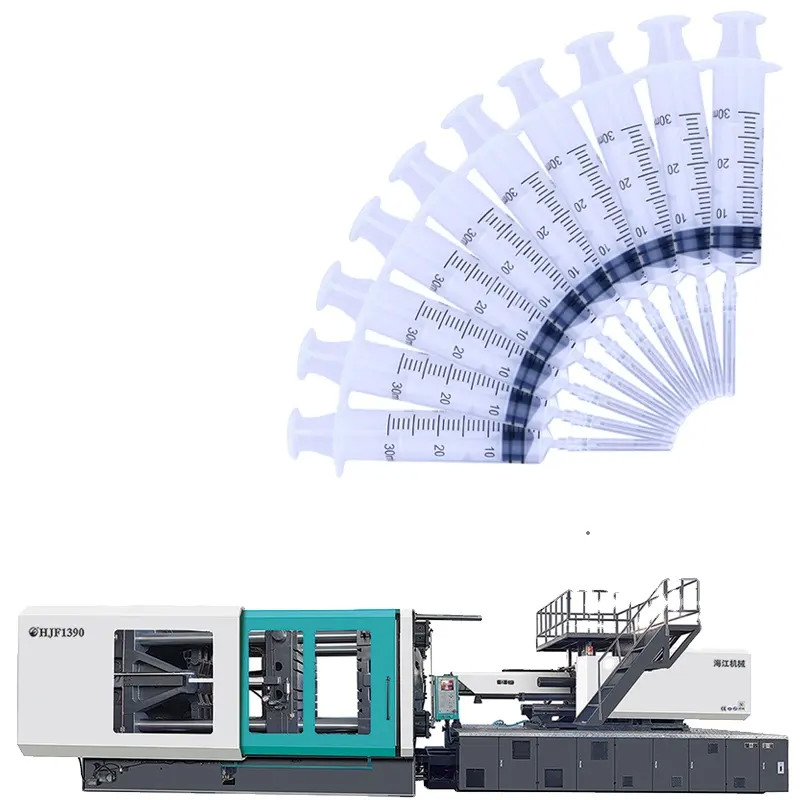

Water / Oil Cooling System Injection Molding Machine With Tolerance Of 0.01mm

Product Details:

| Place of Origin: | Ningbo,China |

| Brand Name: | Haijiang |

| Certification: | ISO9001,CE |

| Model Number: | HJF-780 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | 30000 |

| Packaging Details: | standard shipping packing |

| Delivery Time: | 35 days |

| Payment Terms: | TT,LC,DP |

| Supply Ability: | 300 sets per month |

|

Detail Information |

|||

| SurfaceTreatment: | Polishing | Mould Testing: | Leakage/Stress |

|---|---|---|---|

| Shape: | Customized | Mould Insert: | SKD61 |

| Mould Base: | LKM | Tolerance: | 0.01mm |

| Mould Core: | H13 | Color: | Silver |

| High Light: | Oil Cooling System Injection Moulding Machine,Customized Water Cooling Injection Molding Machine |

||

Product Description

Product Description:

Injection molding molds are an essential component in the manufacturing process of plastic products. These molds are used to shape molten plastic into various forms, allowing for the production of a wide range of plastic products such as toys, household items, and automotive parts.

The Injection Molding Molds offered by our company are designed and manufactured with the highest quality materials and advanced technology to ensure the production of high-quality plastic products. Our molds are compatible with battenfeld molding machines, aotai injection molding machines and other leading brands in the industry.

- Mould Cooling System: Our Injection Molding Molds come equipped with a highly efficient cooling system that ensures the proper and consistent cooling of the molten plastic. This system can be customized to use either water or oil, depending on the specific requirements of the product being molded.

- Surface Treatment: Our molds are treated with a high-quality polishing process that results in a smooth and glossy surface finish on the final product. This not only enhances the appearance of the product but also improves its overall quality and durability.

- Mould Insert: We use high-grade SKD61 material for the inserts in our molds. This material has excellent heat resistance and toughness, making it ideal for use in high-temperature applications.

- Color: Our Injection Molding Molds are silver in color, giving them a sleek and professional appearance. This also makes them easy to clean and maintain, ensuring their longevity and optimal performance.

- Mould Base: The base of our molds is made from LKM, a high-grade steel material known for its exceptional strength and durability. This ensures that our molds can withstand the high pressure and temperature of the injection molding process, resulting in precise and accurate product formation every time.

With our Injection Molding Molds, you can be assured of a reliable and efficient production process that delivers high-quality plastic products. Contact us today to learn more about our molds and how they can benefit your manufacturing process.

Features:

- Product Name: Injection Molding Molds

- mould Cavity: Single/Multi

- color: Silver

- mould CorePulling System: Hydraulic

- mould Base: LKM

- mould Testing: Leakage/Stress

- microprocessor injection moulding machine

- microprocessor injection moulding machine

- aotai injection molding machine

Technical Parameters:

| Product Name | Injection Molding Molds |

|---|---|

| Mould Core | H13 |

| Runner System | Hot/Cold |

| Mould Ejection System | Hydraulic/Pneumatic |

| Mould Insert | SKD61 |

| Mould Testing | Leakage/Stress |

| Mould Life | 100000 Shots |

| Color | Silver |

| Mould Cavity | Single/Multi |

| Material | Steel |

| Mould Core Pulling System | Hydraulic |

| Product Name | Injection Molding Molds |

|---|---|

| Mould Core | H13 |

| Runner System | Hot/Cold |

| Mould Ejection System | Hydraulic/Pneumatic |

| Mould Insert | SKD61 |

| Mould Testing | Leakage/Stress |

| Mould Life | 100000 Shots |

| Color | Silver |

| Mould Cavity | Single/Multi |

| Material | Steel |

| Mould Core Pulling System | Hydraulic |

| Compatible Machines | Aotai Injection Molding Machine, Microprocessor Injection Moulding Machine, Battenfeld Molding Machine |

Applications:

Haijiang is a leading brand in the manufacturing of high-quality microprocessor injection moulding machines. Our HJF-780 model, made in Ningbo, China, is a state-of-the-art machine that has gained recognition for its advanced technology, precision engineering, and superior performance.

Our injection molding molds are used in various industries, such as automotive, electronic components, home appliances, medical devices, and industrial machinery. These molds are designed to produce high-quality and efficient production of precision molds for a wide range of applications.

- Brand Name: Haijiang

- Model Number: HJF-780

- Place of Origin: Ningbo, China

- Certification: ISO9001, CE

- Minimum Order Quantity: 1 set

- Price: $30,000

- Packaging Details: Standard shipping packing

- Delivery Time: 35 days

- Payment Terms: TT, LC, DP

- Supply Ability: 300 sets per month

- Mould Ejection System: Hydraulic/Pneumatic

- Tolerance: 0.01mm

- Material: Steel

- Shape: Customized

- Mould Cooling System: Water/Oil

Our injection molding molds are made of high-quality materials and are designed with precision engineering to ensure accurate production and consistent quality. Our advanced technology and strict quality control measures guarantee superior results and reliable and consistent output.

We understand that each industry and application has unique requirements. That's why we offer customized designs and solutions to meet the specific needs of our customers. Our team of experts works closely with clients to provide the best possible solutions for their production needs.

Our injection molding molds are equipped with advanced cooling systems and efficient ejection systems that allow for high productivity and precise shaping of components. Our precise measurement and positioning systems ensure efficient and accurate production, resulting in cost-effective and durable molds.

Our injection molding molds are designed to be user-friendly, with easy maintenance and smooth surface finish. The seamless integration of our molds with our advanced control systems enables optimized production processes and increased competitiveness in the market.

We are committed to producing high-quality products while also taking care of the environment. Our injection molding molds are made with environmentally-friendly materials and sustainable production processes, making them a responsible choice for businesses.

Our injection molding molds are versatile and can be used for a wide range of applications. Whether it's for automotive parts, electronic components, home appliances, medical devices, or industrial machinery, our molds provide innovative solutions for precise and efficient production.

Choose Haijiang for advanced machinery, precision engineering, and customizable solutions for all your injection molding needs. Contact us today to learn more about our products and how they can help improve your production process.

Packing and Shipping:

Our Injection Molding Molds are carefully packaged and shipped to ensure they arrive at their destination in perfect condition. Each mold is individually wrapped in protective materials and placed in a sturdy box for maximum protection during transit.

We also offer customized packaging options to meet the specific needs of our customers. This can include foam inserts, palletizing, and labeling with specific instructions or company logos.

Our molds are shipped via trusted and reliable carriers to ensure timely and safe delivery. We also provide tracking information so you can monitor the progress of your shipment.

For international orders, we take extra care to comply with all export regulations and ensure proper documentation for a smooth customs clearance process.

At Injection Molding Inc., we are committed to providing high-quality products and exceptional customer service. That's why we take great care in packaging and shipping our Injection Molding Molds to ensure they arrive at your doorstep in perfect condition.